| 产品图片Product image |

|

|

| 产品特点Product features |

|

伟迪生高频感应加热设备系列具有频率高(可加热焊接最小0.1mm),体积小,重量轻,故障率低,节能环保(比玻璃陶瓷电子管高频机省电70%),并且焊接点牢固美观精致,被焊件几何形状不受限制,表面花纹不会损伤,金属内部晶体结构不变,退火范围小,无明显焊疤而被广泛应用于金属眼镜制造业,电器电子行业的接插件焊接,小型继电器内部的不接触焊接,制冷业的耐高压焊接,首饰行业各部件间的焊接和金属饰品及金属工艺制造业的焊接。 Wei Edison high frequency induction heating equipment with high frequency (heating welding minimum 0.1mm), small volume, light weight, the failure rate is low, energy saving and environmental protection (than glass ceramic electronic tube machine, high frequency energy saving 70%), and the welding point is firm and beautiful and exquisite, is weldment geometry is not restricted, surface pattern does not damage, metal internal crystal structure unchanged, the annealing range small, no obvious welding scar and is widely used in metal glasses manufacturing, welding connector of the electrical and electronic industry, inside a small relay non-contact soldering, refrigeration industry of high pressure resistance welding, jewelry industry among the components of the welding and metal jewelry and metal process manufacturing welding. |

| 产品参数说明Product parameter description | ||||||||||||||||||||||

Product model WDS04 ultra high frequency machine (split machine) |

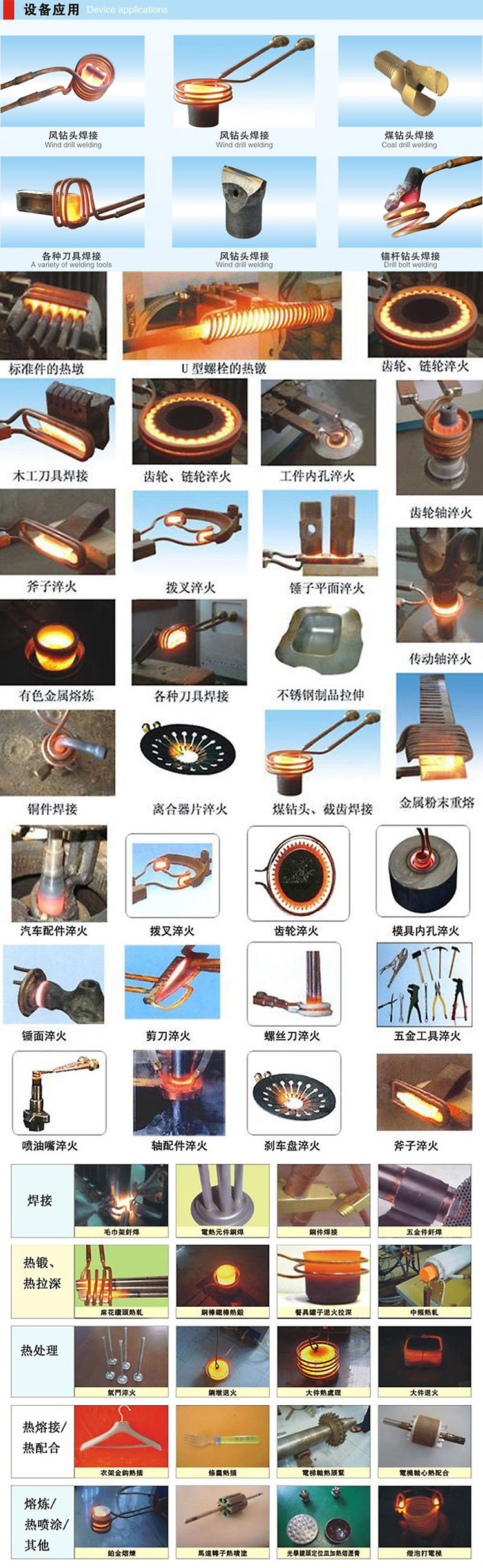

| 产品应用Product application |

|

高频机的高频大电流流向被绕制成环状或其它形状的加热线圈(通常是用紫铜管制作)。由此在线圈内产生极性瞬间变化的强磁束,将金属等被加热物体放置在线圈内,磁束就会贯通整个被加热物体,在被加热物体的内部与加热电流相反的方向,便会产生相对应的很大涡电流。由于被加热物体内存在着电阻,所以会产生很多的焦耳热,使物体自身的温度迅速上升。达到对所有金属材料加热的目的。

在高频机内由一整套独特的电子线路,将从外接电源输入进来的50Hz低频交流电转变成高频20000Hz以上交流电;高频电流加到电感线圈后,利用电磁感应原理转换成高频磁场,并作用在处于磁场中的金属物体上;利用涡流效应,在金属物体中生成与磁场强度成正比的感生电流,电流在金属物体内流动时,会借助于内部所固有的电阻值,利用电流热效应原理生成热量,这种热量是直接在物体内部生成的,所以,这种加热方式,速度快,效率高。如果需要,它可在瞬间熔化任何金属物。而且,它的加热速度和温度是可控的。

主要应用于:

加热1、热锻它主要是把金属工件加热到一定温度后(根据材质不同加热温度也不同),通过冲床、锻床或其他形式把工件锻压成其他形状。例如:表壳、表胚、拉手、模具附件、厨房餐具用品、工艺品、标准件、紧固件、机械零件加工、铜锁、铆钉、钢钎、钎具的热挤压等等。

2、热配合它主要是指不同种金属之间或金属与非金属之间通过对金属的加热,利用热扩张或热熔解的原理使两者连接在一起。例如:铜芯与铝片、喇叭网的埋值焊接、钢塑管的复合、铝箔的封口(牙膏皮)、电机转子、电热管封口等等。

3、熔炼它主要是指通过对金属的高温,把金属化成液体,主要适用于铁、钢、铜、铝、锌以及各种贵重金属。如金、银的熔化。

热处理

它主要是通过对工件的加热等处理后使得金属材质的硬度发生变化,具体应用如下:

1、 各种五金工具、手工具。如钳子、板手、锤子、斧头、旋具、剪刀(园艺剪)等的淬火;

2、 各种汽车、摩托车配件。如曲轴、连杆、活塞销、链轮、铝轮、气门、摇臂轴、传动半轴、小轴、拔叉等的淬火;

3、 各种电动工具。如齿轮、轴心;

4、 机床行业类。如机床床面、机床导轨等的淬火;

5、 各种五金金属零件、机械加工零件。如轴类、齿轮(链轮)、凸轮、夹头、夹具等的淬火;

6、 五金模具行业。如小型模具、模具附件、模具内孔等的淬火;

焊接

它主要是通过加热到一定温度使焊料熔化,从而把两种一样材质或不同材质的金属连接在一起,具体应用如下:

1、各种五金刀具的焊接:金刚石刀具、磨具、钻具、合金锯片、硬质合金车刀、铣刀、铰刀、刨刀、木工钻头等的焊接;

2、各种五金机械配件的焊接:五金卫浴产品、制冷铜配件、灯饰配件、精密模具配件、五金拉手、打蛋器、合金钢与钢、钢与铜、铜与铜等同种金属或异种金属的银焊、铜焊;

3、复合锅底焊接主要用于圆形、方形及其它异形平面不锈钢锅底与铝片的三层钎焊,也可用于其它金属平面钎焊。

4、电热水壶(电咖啡壶)的发热盘焊接主要用于不锈钢平底、铝片与各种形状电热管之间的钎焊。

退火

1、各种不锈钢行业的退火。如不锈钢盆、罐的退火拉伸、退火卷边以及水槽的退火、不锈钢管、不锈钢餐具、不锈钢杯等;

2、其他各种金属工件的退火。如高尔夫球头、球杆、铜锁头、五金铜配件、菜刀把、刀刃、铝锅、铝桶、铝散热器以及各类铝制品相关模具如制作各种感应圈 应先准备好各种模具 沿的模具制作的出来的东西既快又漂亮。

应用于以下行业

一.热处理行业:

1.五金工具高频淬火热处理,如;虎钳、锤、大力钳、扳手。

2.各种汽、摩配高频淬火热处理,如:曲轴、连杆、活塞销、凸轮轴、气门、变速箱内的各种齿轮、各种拔叉、各种花键轴、传动半轴、各种小轴、曲柄销、各种摇臂、摇臂轴等高频淬火热处理。

3.液压元件,如:柱塞泵的柱塞、转子泵的转子、各种阀门上的换向轴、齿轮泵的齿轮等高频淬火热处理。

4.各种电动工具齿轮、轴的高频淬火热处理。

5.各种木工工具,如:斧头、刨刀等热处理。

二.焊接行业:

1.各种车刀、刨刀、铣刀等机加工刃具的焊接。

2.各种金钢石工具的焊接,如:金钢石锯片、金钢石钻具的焊接。

3.各种一字型钎头、柱齿钎头、燕型煤钻头、铆杆钻头。

4.各种采煤机截齿的焊接、各种掘机截齿的焊接。

5.各种机械用刀具的焊接。

三.锻压行业:

1.各种标准件,非标准件的热墩。

2.钳子、扳手等五金工具的锻前加热等。

3.钎具、钎尾尾柄、锥体、钎头锻造等。

The high frequency high current flow is made of a circular or other shaped heating coil (usually made of copper). Through this very moment change strong magnetic bundle is produced in the coil, metal is heated object placed in the coil, the magnetic bundle will be through the heated objects in the object to be heated with internal heating current in the opposite direction, will produce corresponding to the large eddy current. Because of the heat resistance, there will be a lot of Joule heating, so that the temperature of the object itself is rising rapidly. To achieve the purpose of heating all metal materials. |

| 使用效果图Use effect diagram |

|

|

| 物流/快递说明Logistics / courier |

|

|

| 联系方式Contact information |

|

联系地址:广东省佛山市顺德区伦教镇羊额周地工业区永安路9号 联系电话:13889944117 林小姐 公司电话:0757-28797980 传真号码:0757-28797987 腾讯QQ:1284792927 Contact address: Yongan City Guangdong Province Foshan Shunde Lunjiao Town shee p week Industrial Zone No. 9 Contact phone: 13889944117 Company phone: 0757-28797980 Fax number: 0757-28797987 QQ:1284792927 |

2015致客户的一封信2015 a letter to clients |

|

尊敬的客户:

您们好! 今天,伟迪生精密机电有限公司迎来了成立六周年的纪念日。这是一个特殊的日子,在过去的六年中,公司全体同仁共同努力迈过的每一个脚印都值得我们深深的回忆。在此,我要感谢广大新老客户六年来对伟迪生公司的大力支持,同时特别感谢公司各位同仁六年来的辛勤付出。我谨代表公司及我个人向您们表示最忠诚的祝福。 首先怀着感恩的心情,真诚感谢您们对伟迪生公司的关注和支持!请允许我占有您的一点点时间来介绍我们企业:伟迪生精密机电有限公司是在感应加热设备行业最具实力的厂家之一,专业研发、生产高频、中频、超高频等感应加热设备系列产品及电腐蚀金属打标设备系列产品,主要用于各行各业对金属材料的热加工、热处理、热装配及焊接、熔炼等工艺中,目的是用机器取代人工,提高贵公司产品的质量和效率,我们提供的产品质优价廉,组件采用进口于日本、德国,为您的产品提供了良好的质量、价值和安全保证。公司秉承服务至上,技术领先的经营理念,产品销往全国、海外。 感应加热设备作为现代五金行业的必需品,越来越受到企业的喜爱和追捧。我们很荣幸能够成为您购买感应加热设备的顾问并有机会为您提供服务。只要您看完这封信,就是对我们工作的信任和支持!只要您对我们的质量、服务提出要求和建议,就能给我们带来鼓舞与启迪! 在过去的日子里,不知道您对感应加热设备抱有什么样的态度,但为将来着想,我们还是真心希望您使用感应加热设备! 感应加热技术是目前对金属材料加热效率最高、速度最快,且低耗环保的先进技术。感谢您在过去六年时间内对伟迪生公司的鼎力支持,因为有您的支持我们才能有今天的发展与进步。 通过六年的发展与积累、我们深深认识到了您在我们发展过程中的重要性。为了能跟您长久的配合、我们必须要有进一步的提升,同时为了能给您提供更好的服务与更高附加值的产品我们必须从经营体制、产品设计与制造及人员储备方面下大力气、从而才能追赶您快速发展的脚步。 我们的公司虽然经过了六年的发展、但目前的状况亦如一个襁褓孩子、还需要您多些包容与理解。 在过去的六年里、我们一直在致力于为您开发最好用的操作系统、及为您寻找价格最低、原材料上胜的供应商、从而呈现性价比最优的产品给您。 从我们的目前800台的年销量上来看,我想这一方式也确实得到了您的认可。但随着时间的推移、我们发现高频机这一尚未完全标准化产品确实存在很多的可优化空间、同时,经过时间的验证,我们发现某些部件虽然价格低廉但其耐久性与可靠性确实有待推敲、这样一来,我们虽然帮您节约了初期采购成本、但对于追求《永续经营》理念的您来讲,这无疑会给您自主品牌的创建路上增添了绊脚石。

所作的这一切,只是为了一个目标、能跟上您发展的脚步、得到您的认可,与您长久的合作下去。 值此周年的纪念日,我们衷心的道一声“谢谢!”,给您送来祝福: 祝您事业顺利,身体健康,阖家欢乐!

详情资料请登录我公司网站:http://www.weidisheng.com

伟迪生精密机电有限公司 地址:广东省佛山市顺德区伦教镇羊额周地工业区永安路9号 联系人: 13889944117 林小姐 微信号:13889944117 QQ:1284792927 邮箱:1284792927@qq.com

You are good!

Today, wei disheng precision machinery co., LTD. Was established in the sixth anniversary of the day. This is a special day, in the past six years, the company all my colleagues work together to move beyond every footprint is worthy of our deep memories. Here, I would like to thank the new and old customers to wei in six years to have the company’s strong support, at the same time, special thanks to the company everyone colleague in six years of hard work. I, on behalf of the company and my personal greeting you most loyal blessing.

First of all, with the feelings of gratitude, sincere thank you to wei disheng company’s concern and support! Please allow me to occupy you little time to introduce our company: wei disheng precision machinery co., LTD., is in the induction heating equipment industry one of the most powerful manufacturers, professional research and development, production of high frequency, intermediate frequency, ultra high frequency induction heating equipment series products and electric corrosion of metal marking equipment series products, mainly used in all walks of life the hot working of metal material heat, heat treatment, assembly and welding, such as smelting process, the purpose is to use machine to replace artificial, improve the quality and efficiency of your company products, we provide products of high quality and low price, adopts imported from Japan, Germany, for your products provide a good quality, value and security guarantees. Companies adhering to the service is supreme, leading technology business philosophy, products are exported to the country and overseas.

Induction heating equipment as a necessity of modern hardware industry, more and more popular with companies and sought after. We is a great pleasure to be your buying consultant in induction heating equipment and have the opportunity to provide service for you. As long as you finish reading this letter, is to trust and support of our work! As long as you have for our quality and service requirements and Suggestions, will bring us inspiration and enlightenment!

In the past days, don’t know what kind of attitude towards you for induction heating equipment, but for the sake of the future, we sincerely hope that you are using induction heating equipment.

Induction heating technology is the metal material heated, the fastest, most efficient and low consumption advanced technology in environmental protection. Thank you in the past six years of wei have the support of the company, because with your support we can have today’s development and progress.

Through six years of development and accumulation, we deeply realized the importance of you in our development process. In order to can cooperate with you for a long time, we must have further ascension, at the same time in order to provide you with better service and higher added value products we must from the management system, product design and manufacturing and personnel reserve makes, thus can catch you quickly development steps.

Although our company after six years of development, but the current situation as an infant and children need you more tolerance and understanding.

In the past six years, we have been working on for you to develop the best operating system, and for you to find the lowest price, raw material suppliers, thus rendering the optimal ratio of the products to you.

From our current annual sales of 800 units, I think this way is to get your approval. But as time goes on, we found that the high frequency machine this is not fully standardized products there is a lot of space, can be optimized at the same time, after time of verification, we found some parts while prices are low but its durability and reliability is questionable, in this way, we help you to save the initial purchase cost, but for the pursuit of the concept of “sustainable development” will tell you, this will definitely give you added a stumbling block to create the way of independent brands.

Do it all, just for a goal, you can keep up with development steps, get your recognition, long-term cooperation with you.

On the occasion of the anniversary, we sincerely say “thank you!” , send your blessing:

I wish you have a long career, healthy body, a happy family!

Detail information please visit our website: http://www.weidisheng.com

Wei disheng precision machinery co., LTD

Address: lunjiao town, shunde district, foshan city, guangdong province sheep 9 weeks to wing road industrial area

Contact: linyuanmei 13889944117

Micro signal:

QQ:1284792927

|

| 上一篇: 供应佛山硬质高速合金钢商标wds-950打标机 | 下一篇: 供应佛山高频35kw铜管加热机 |